Ever imagined the future of urban travel, where the skies filled with innovation? Well, this is slowly becoming a reality through the innovation of Electric Vertical Take-Off and Landing (eVTOL) aircraft. These marvels of engineering are set to revolutionise how we navigate cityscapes. So, buckle up as we unravel the complex craftsmanship and technology that breathe life into these futuristic vehicles.

Design and Engineering: A Symphony of Precision and Innovation

At the heart of eVTOL design lies a commitment to agility, efficiency, and safety, harmonising lightweight construction with powerful propulsion systems. Distributed Electric Propulsion (DEP) technology is a key design feature of many eVTOLs, allowing for multiple electric motors to be distributed throughout the aircraft. This provides several advantages, including improved efficiency, and manoeuvrability.

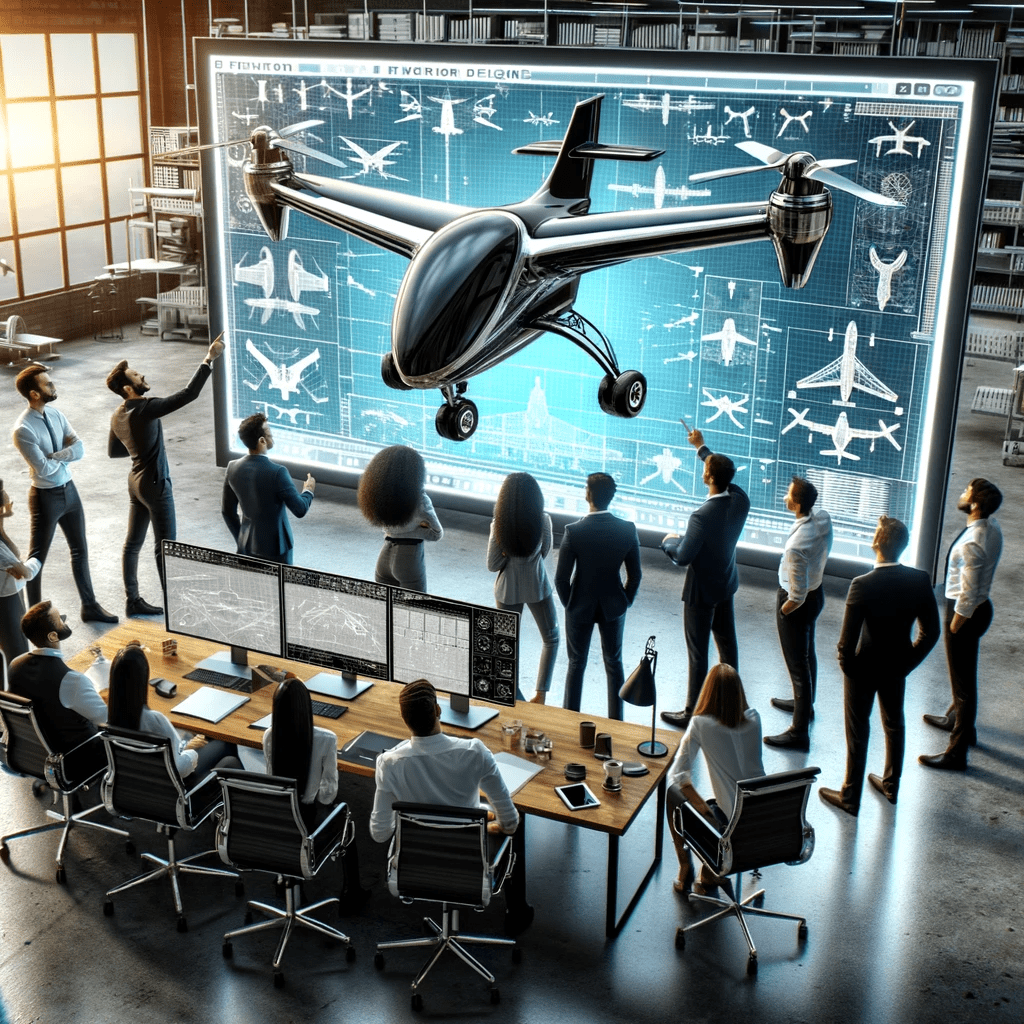

The Journey from Blueprint to Vehicle Creation

The journey from eVTOL blueprint unfolds in the following stages:

- Design: Computer-Aided Design (CAD) software is used to create detailed 3D models of the eVTOL, taking into account aerodynamics, performance, and manufacturability.

- Engineering: Engineers develop detailed plans for each component, specifying the materials and manufacturing processes to be used.

- Manufacturing: Advanced machinery and skilled workers fabricate, assemble, and fine-tune each part of the eVTOL.

- Testing: eVTOLs undergo rigorous safety and performance testing before being certified for flight.

- Certification: Regulatory bodies, such as the FAA, issue airworthiness certificates to eVTOLs that meet their safety standards.

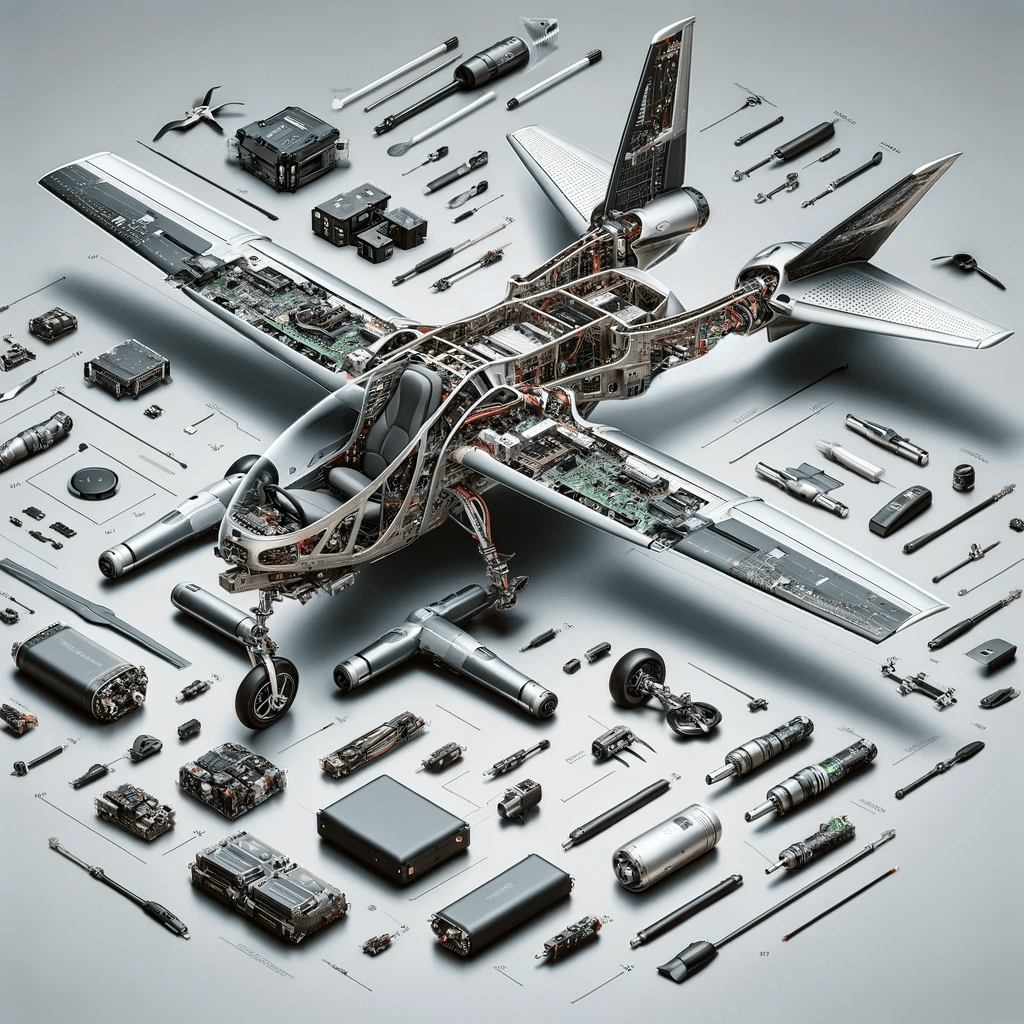

Critical Components of an eVTOL

Each eVTOL is a symphony of critical components:

- Airframe: The lightweight yet sturdy skeleton of the eVTOL, often made from carbon fiber composites and aluminium.

- Propulsion System: The heartbeat of the eVTOL, powered by multiple electric motors.

- Batteries: The energy source for the eVTOL, providing high-energy density for extended range.

- Flight Control Systems: Sensors and actuators that work together to control the movement of the eVTOL.

- Avionics: The onboard computer system that manages navigation, communication, and other essential functions.

Materials: A Balancing Act of Strength and Aerial Lightness

Materials are chosen with a masterful eye, with carbon fiber composites and advanced polymers balancing strength with aerial lightness. Carbon fibre composites offer exceptional strength-to-weight ratios, making them ideal for eVTOL structures, while advanced polymers provide flexibility and resistance to corrosion.

Battery Technology: Pushing Boundaries for Extended Range

Battery technology is in relentless pursuit of higher energy densities and longer ranges, aiming to push boundaries beyond 300 kilometres on a single charge. Solid-state batteries, for instance, hold promise for significantly increased energy densities and faster charging times.

Safety: A Paramount Concern

Safety is essential in the development of eVTOL aircraft. Innovative systems featuring independent rotors and proactive failure detection are being implemented to ensure the highest levels of safety. Redundancy is also a key design principle, with multiple backup systems in place to prevent critical failures.

Challenges on the Path to Expansion

The path to eVTOL all-presence isn’t without its challenges:

- Complexity: Crafting high-quality, reliable eVTOLs is a complex undertaking that requires a deep understanding of aerodynamics, propulsion systems, and materials science.

- Costs: The initial costs of eVTOL development and manufacturing are steep, but these costs are expected to decrease as the industry matures.

- Technology and Materials Adoption: Embracing new technologies and materials, like 3D printing and advanced composites, is crucial for overcoming manufacturing challenges and improving performance.

- Collaborative Manufacturing: Strengthening the bond between eVTOL manufacturers and suppliers is essential for streamlining production processes and ensuring quality control.

- Automation and Efficiency: Automation and model-based engineering can drive efficiency and cost reduction in eVTOL manufacturing.

- Charging Infrastructure: Developing a reliable and efficient charging infrastructure is critical for widespread eVTOL adoption.

- Regulatory Approval: Obtaining regulatory approval from aviation authorities is a complex and time-consuming process that requires extensive safety testing and documentation.

- Public Acceptance: Building public acceptance for eVTOL technology is crucial for its widespread adoption. This involves addressing concerns about noise, safety, and the impact on urban environments.

The Future: Shaped by Investment, Innovation, and Demand

As we gaze into the future of eVTOLs, we see a landscape shaped by government investment, increasing private funding, and a growing demand for sustainable urban travel solutions. eVTOL technology has the potential to revolutionise urban transportation, offering a faster, more convenient, and environmentally friendly alternative to traditional ground-based transportation.